The tna robag® 5 is the latest addition to the popular tna robag® 5 range of vertical form, fill and seal (VFFS) packaging solutions. The tna robag® 5 is the world’s fastest VFFS packaging system and can achieve ultra-high speeds of up to 300 bags per minute. Available in multiple jaw configurations to support a wide variety of bag types and sizes.

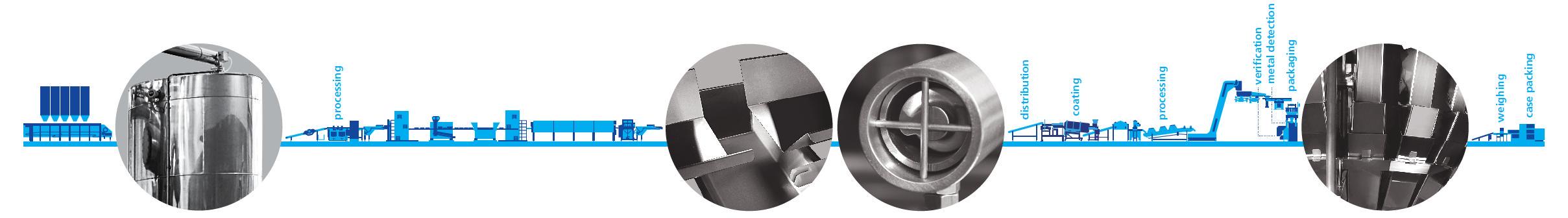

The addition of the tna robag® 5 to the line up of food processing and packaging solutions, positions tna as the only global supplier to offer a complete, ultra-high speed bagging and case packing solution for small pillow-style bags in the snacks and confectionery segments. This highly compact and fully integrated system solution allows snacks and confectionery manufacturers to double their outputs with the same footprint.

• Double your outputs with ultra-high speeds of up to 300bpm, while maintaining the same foot print (or less) and with lower waste and rejects

• Convert twin packaging lines to single packaging lines, reducing costs of ownership and maintenance with the smallest footprint possible, dual side access for operation and service

• Increase your weighing efficiency and speed with the new tna intelli-weigh® 0220 omega, a fully integrated, high-performance multi-head scale with more heads for more combinations

• Reduce maintenance costs and time by collecting highly efficient diagnostics with tna’s new real-time CXE controller, a single-board computer based on embedded Linux RTOS with a scan rate of 1ms

• Control the entire line from a single location using tna intelli-sys® software

• Minimise manual adjustments and intervention through automation thanks to the highly efficient, yet simple user interface (UI) of the tna robag® 5

• Ensure highest food safety standards and meet global food safety regulations with a full stainless-steel design and tna’s patented metal detection and integrated verification solutions

• Achieve ultra-high speeds with tna’s new continuous motion ultrasonic back seal that supersedes thermal technology

• Compact design with “one machine per bagger configuration”

• 38.1cm (15inch) colour touch screen

• New innovative semi-rotary bag shelving

• Quick change, tool less changeovers and easy maintenance access

• Inclined check-weigher on the infeed conveyor to control accuracy of bag weights from bagger

• Unrivalled speeds thanks to patented semi-rotary bag stacking technology

• Uses Innovative semi-rotary stacking motion instead of inefficient vacuum pick and drop technology that leads to breakage of product and machine downtime

• Designed at a width of only 1220mm and optional twin packer configuration

• Utilises five pneumatic actuators drastically reducing power and air requirements (compared use up to 100 pneumatic actuators)

• Made with fewer moving parts and designed for tool-less changeovers

• Seamless integration with bag maker via operative monitors

For over 30 years, tna and its family of brands has helped food manufacturers capitalise on this industry that’s booming in gummies, hard candies, chocolates and more. With more than 14,000 installations in over 120 countries, tna’s complete line of solutions brings simplicity, flexibility and performance to candy-making production lines everywhere – and can do the same for you!